Logistics

Logistics is the management of networked processes inside and outside the company. Our processes interlock like chain links, thereby directly or indirectly contributing to your gain and benefit. Safe loading, concrete work instructions and clear communication are our top priorities.

Logistics at a glance:

The value chain of specified components and management of the procurement risk

Clearly structured flow of goods, knowledge and finance

Power supply for test runs

Spare parts service

The delivery of spare parts packages forms part of our service package and is, accordingly, a part of each project. Upon request, we can keep spare parts available 24/7 – these can be of crucial importance in the event of a shutdown.

Spare parts service at a glance:

24/7 availability of spare parts

Service level agreements

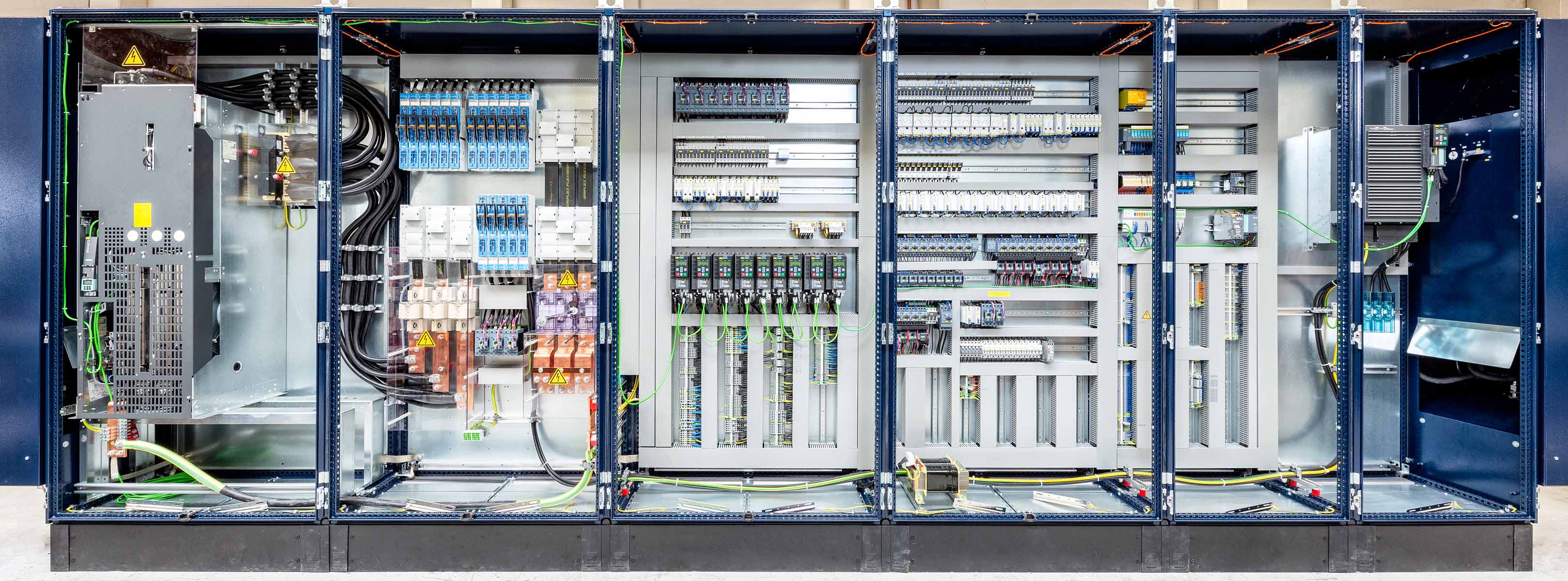

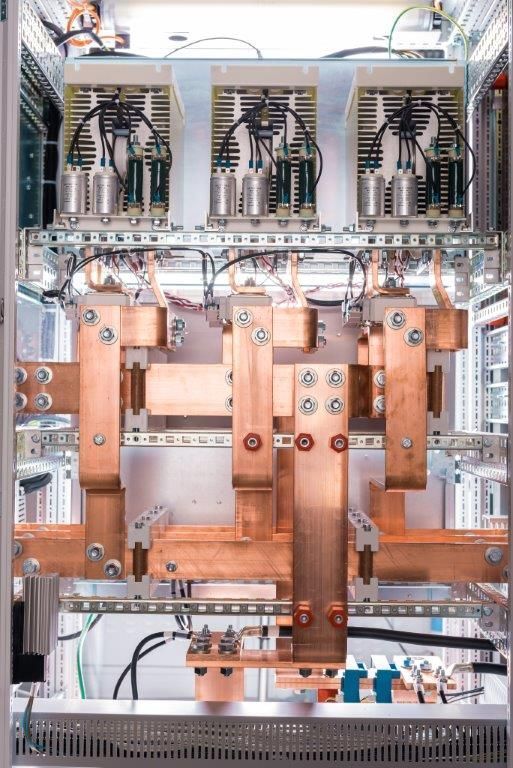

As our client, you receive a service fixed in the SLA’s for all processes, from the test field to delivery to the location, at a negotiated price. In addition to installation and commissioning, our ramp-up engineers also take care of on-site (technical) supervision, as well as cable harness testing. We test all of our systems according to the routine test report outlined in EN 61439-2. The use of checklists enables us to consistently keep track of a project and its progress and to carry our comprehensive tests. Anyone who would like to convince themselves of our work can gladly test out the system themselves.

Service Level Agreements at a glance:

Commissioning

Supervision on site

Testing of the systems according to the routine test protocol in accordance with EN 61439-2

Various levels of documentation

Coordinated tests in the test field

Commissioning and test run

Holistic handling of the logistical project including auxiliary materials and transport aids

Loading and load securing

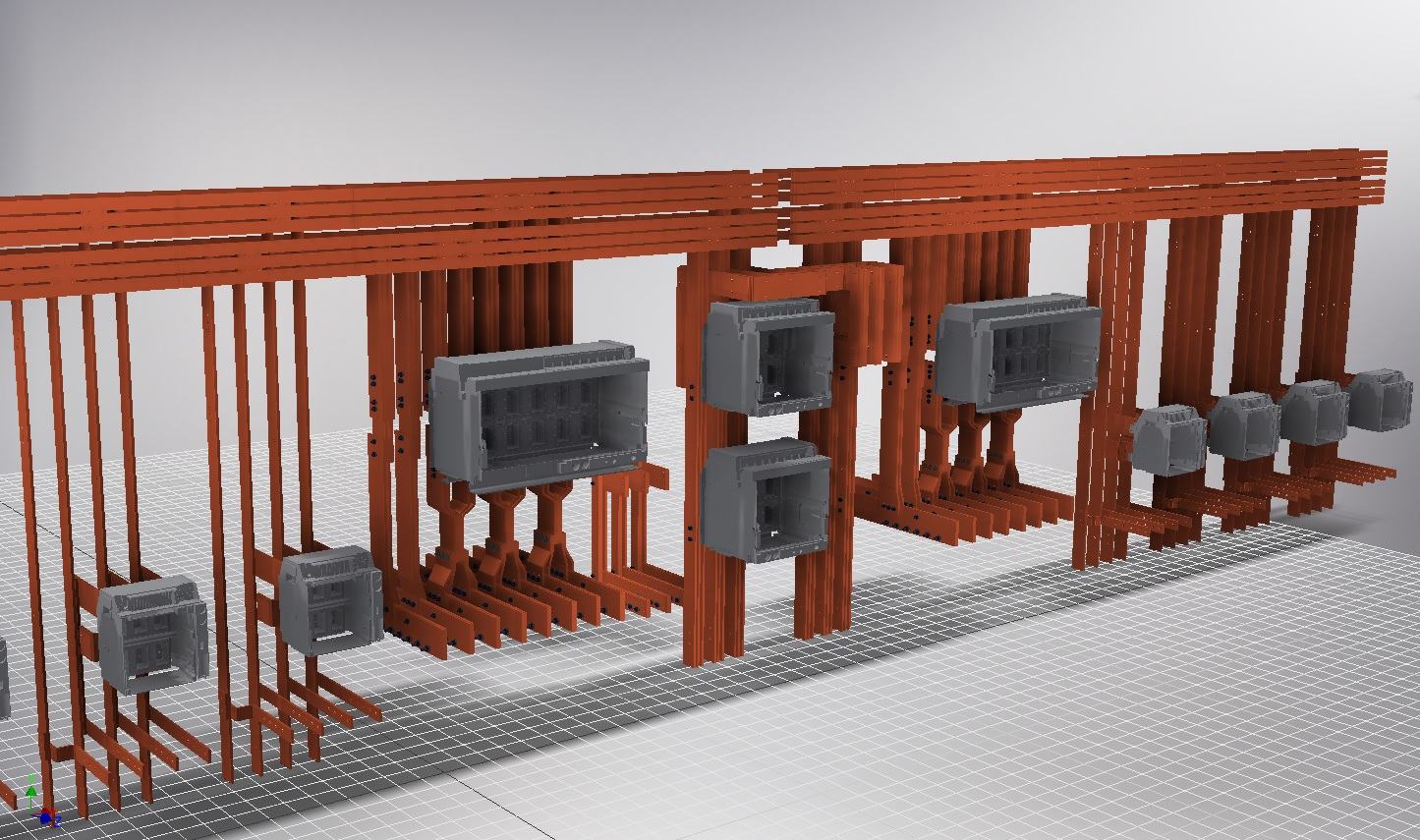

Mechanical production

The processing of assemblies with Perforex ©, a vertical processing centre, guarantees suitable corrosion protection for your surfaces. The choice of materials and suitable standard components is key to avoiding chips in the assemblies. This is why we mainly rely upon manufacturers who can offer the necessary range of accessories.

Mechanical production at a glance:

The processing of assemblies with Perforex ©

Suitable corrosion protection for every type of service

The avoidance of chips in the assemblies

Efficient use of personnel and material

In addition to regular training, our skilled workers also benefit from flexible working hours and a strong sense of team cohesion. This leads not only to increased efficiency, but also to a higher level of employee motivation and, in turn, to increased productivity.

Environment and waste management

What we do today determines what the world will look like tomorrow. For this reason, we recycle our materials where possible and avoid single-use packaging to also make a sustainable impact on our environment.

Holistic planning, control, coordination and implementation

We see ourselves as a holistic partner who accompanies you from the planning, management and coordination to the implementation and control of your processes.